Custom Metal Stamping Manufacturer for Precision Components

High-precision metal stamping solutions supported by engineered tooling and controlled production processes to deliver tight tolerances and consistent part accuracy. Our manufacturing capability is designed to support reliable mass production for automotive, electronics, and industrial applications.

Metal Stamping Capabilities

- Progressive Die Stamping

- High-efficiency stamping process for complex parts and large-volume production with consistent accuracy.

- Single & Compound Die Stamping

- Flexible stamping solutions suitable for simpler geometries and lower-volume requirements.

- Blanking, Piercing & Forming

- Comprehensive stamping operations to produce accurate and functional metal components.

- High-Volume Production Support

- Processes engineered to maintain stable output and repeatable quality in mass production.

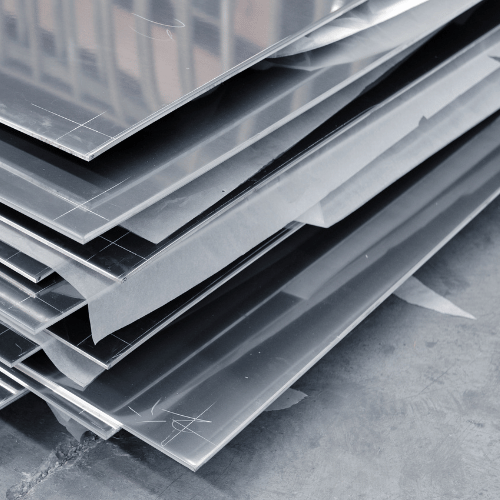

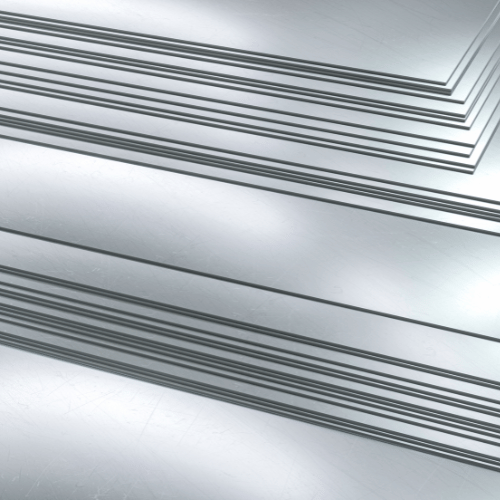

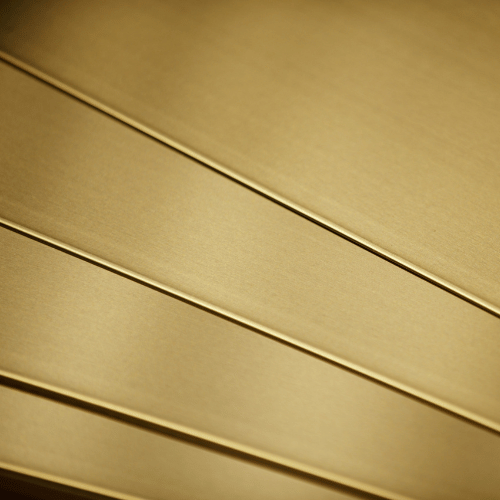

Materials We Support

Steel (Carbon Steel)

Stainless Steel

Brass

Tooling & Die Engineering

Mold & Dies Design Based on Part Function and Tolerance

Tooling designs are developed according to part geometry, tolerance targets, and application requirements.

DFM-Driven Design Approach

Design-for-Manufacturing analysis is applied to reduce tooling risk and improve production efficiency.

Mold Design Review

Mold designs are reviewed to ensure manufacturability, stable molding performance, and reduced risk before tooling production.

Certified for Quality and Reliability

ISO 14001:2015

IATF 16949:2016

ISO 9001:2015

Why Choose Banshu Plastic

Integrated Engineering & Manufacturing

From design to mass production, every process is handled in-house to ensuring precision, speed, and consistent quality.

Certified Quality & Global Standards

Our quality system complies with ISO 14001, ISO 9001, and IATF 16949, supported by strict inspection and continuous improvement culture.

Proven Experience & Trusted by Industry Leaders

Decades of experience serving automotive, electronics, and home appliance manufacturers across Asia.

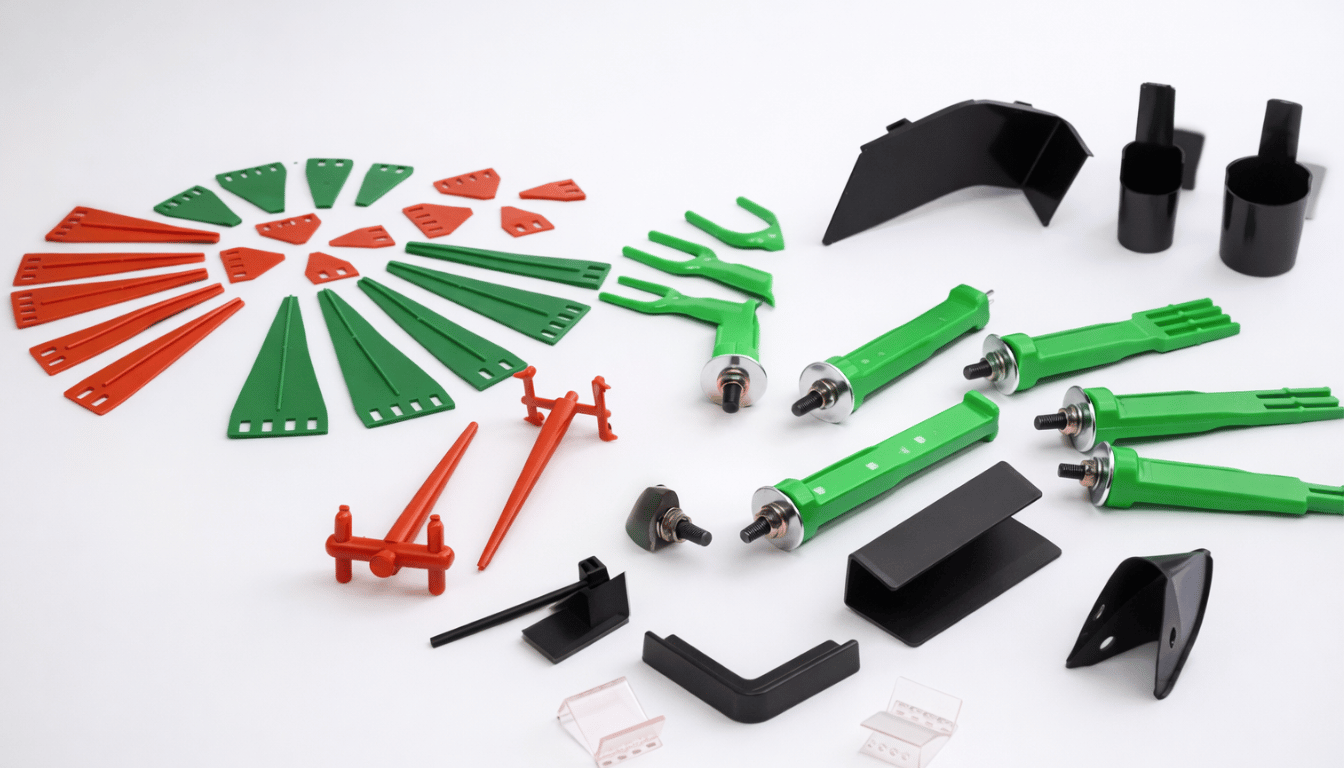

Industries Served

Quality Molded Parts for Your Industry Needs

Automobile Parts

Motorcycle Parts

Home Appliance Parts

Other Parts

Frequently Ask Questions

Metal stamping is a manufacturing process that forms metal sheets into specific shapes using a press and precision dies. The process typically includes material feeding, stamping or forming, cutting or piercing, and finishing. It enables high-speed, repeatable production of accurate metal components for industrial applications.

Metal stamping is performed by placing a metal sheet or coil into a stamping press equipped with a custom-designed die. The press applies controlled force to shape, cut, or form the material according to the required design. In industrial production, proper die design, material selection, and press control are essential to ensure consistent quality and dimensional accuracy.