Precision Mold & Dies Manufacturing for High-Accuracy Production

We provide high-precision mold and dies manufacturing designed for accurate dimensions, consistent quality, and efficient mass production. Supported by advanced machining and experienced engineers, our tooling solutions ensure stable performance and reliable production results.

Our Mold & Dies Capabilities

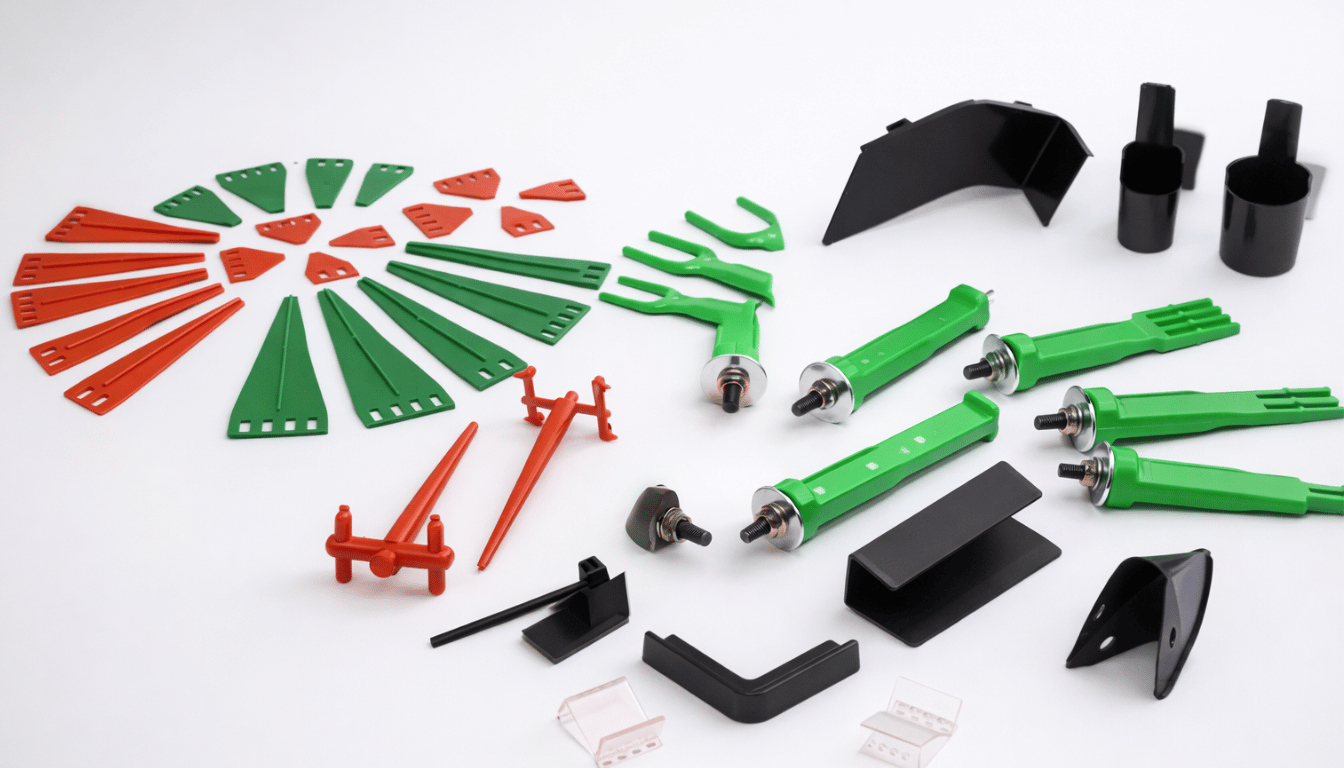

- Injection Mold

- Custom injection molds engineered for stable quality and consistent production.

- Precision Mold

- High-accuracy molds with tight tolerances for complex and technical parts.

- Multi-Cavity Mold

- Productivity-focused molds designed for balanced flow and uniform output.

- High-Volume Production Mold

- Durable molds optimized for long mold life and efficient cycle time.

- Mold & Dies Solution

- End-to-end mold and dies solutions engineered for precision, durability, and stable mass production performance.

Engineering & Design Process

Step 1

Inquiry & Requirement Confirmation

Customer submits an inquiry, drawing, or sample. Our team reviews the product application, specifications, and production requirements.Step 2

Feasibility Study & Quotation

Engineering conducts a feasibility study on design and manufacturing processes, followed by cost calculation and quotation submission.Step 3

Product Development & Mold Preparation

Mold design, review, and sampling trials (T0–T1–T2) are performed to ensure the product meets technical and quality requirements.Step 4

Approval & Production Planning

After sample approval, quality documentation, machine capacity, and production planning are prepared for mass production readiness.Step 5

Mass Production & Quality Assurance

Mass production is executed with continuous monitoring of output, quality performance, and on-time delivery to the customer.Engineering & Design Excellence

Mold & Dies Design Based on Part Function and Tolerance

Tooling designs are developed according to part geometry, tolerance targets, and application requirements.

DFM-Driven Design Approach

Design-for-Manufacturing analysis is applied to reduce tooling risk and improve production efficiency.

Mold Design Review

Mold designs are reviewed to ensure manufacturability, stable molding performance, and reduced risk before tooling production.

Certified for Quality and Reliability

ISO 14001:2015

IATF 16949:2016

ISO 9001:2015

Why Choose Banshu Plastic

Integrated Engineering & Manufacturing

From design to mass production, every process is handled in-house to ensuring precision, speed, and consistent quality.

Certified Quality & Global Standards

Our quality system complies with ISO 14001, ISO 9001, and IATF 16949, supported by strict inspection and continuous improvement culture.

Proven Experience & Trusted by Industry Leaders

Decades of experience serving automotive, electronics, and home appliance manufacturers across Asia.

Industries Served

Quality Molded Parts for Your Industry Needs

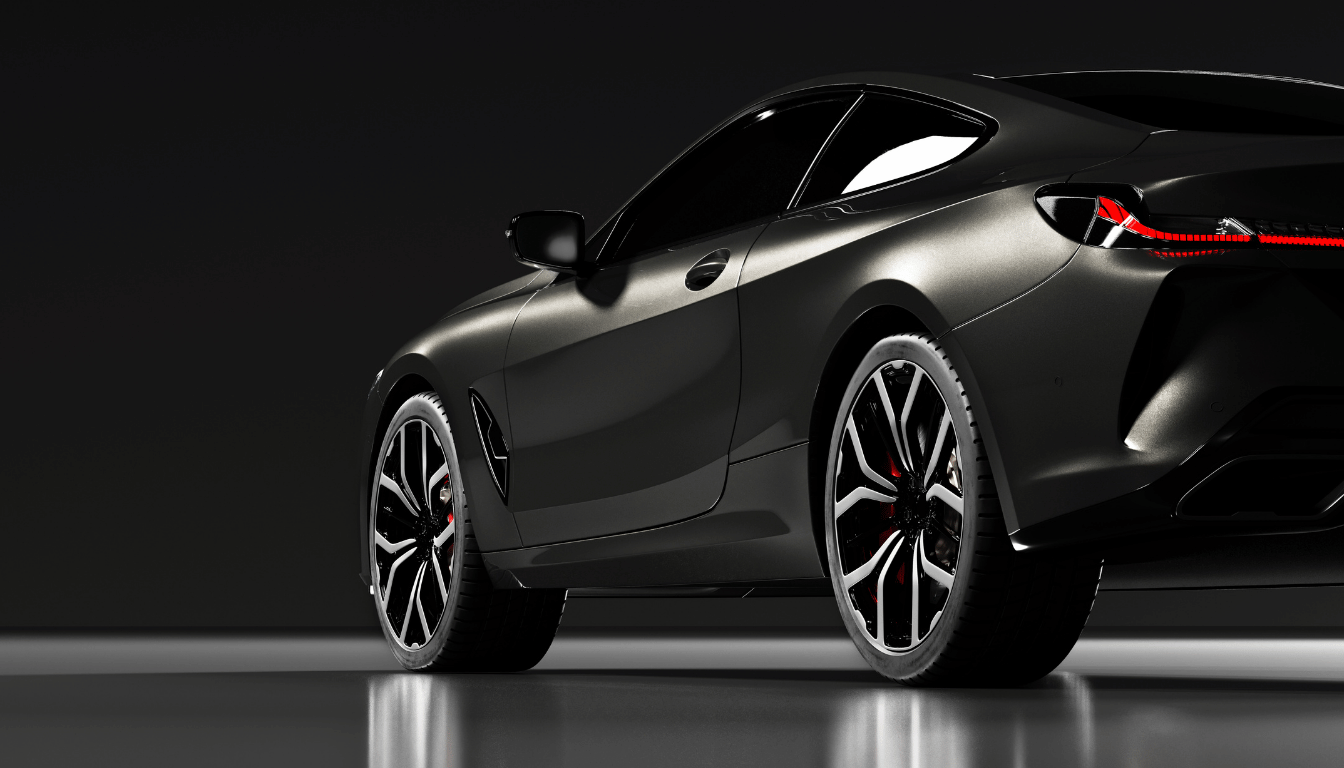

Automobile Parts

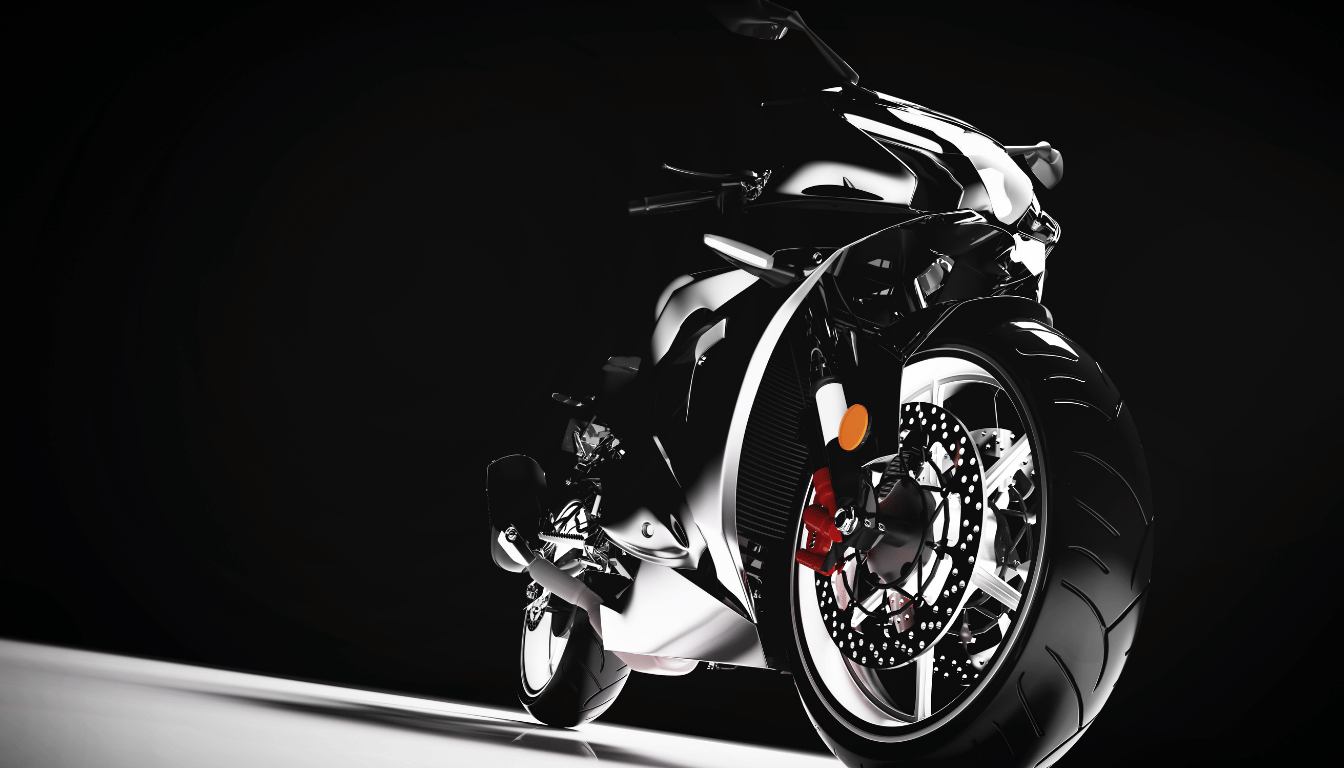

Motorcycle Parts

Home Appliance Parts

Other Parts

Frequently Ask Questions

A die and a mold are precision tools used in manufacturing to shape raw materials into finished parts. A mold is primarily used in plastic injection molding to form plastic components, while a die is commonly used in metal forming processes such as stamping or casting. Both are critical for achieving accuracy, repeatability, and consistent quality in mass production.

In manufacturing, a mold refers to a custom-designed tool that forms molten or softened material into a specific shape. In plastic injection molding, the mold defines the part’s geometry, surface finish, dimensional accuracy, and production efficiency, making it a key factor in overall product quality.

The die and mold making process typically includes several key stages:

Design & Engineering – Product and mold design based on part requirements and material selection.

Material Preparation – Selection of appropriate tool steel or mold materials.

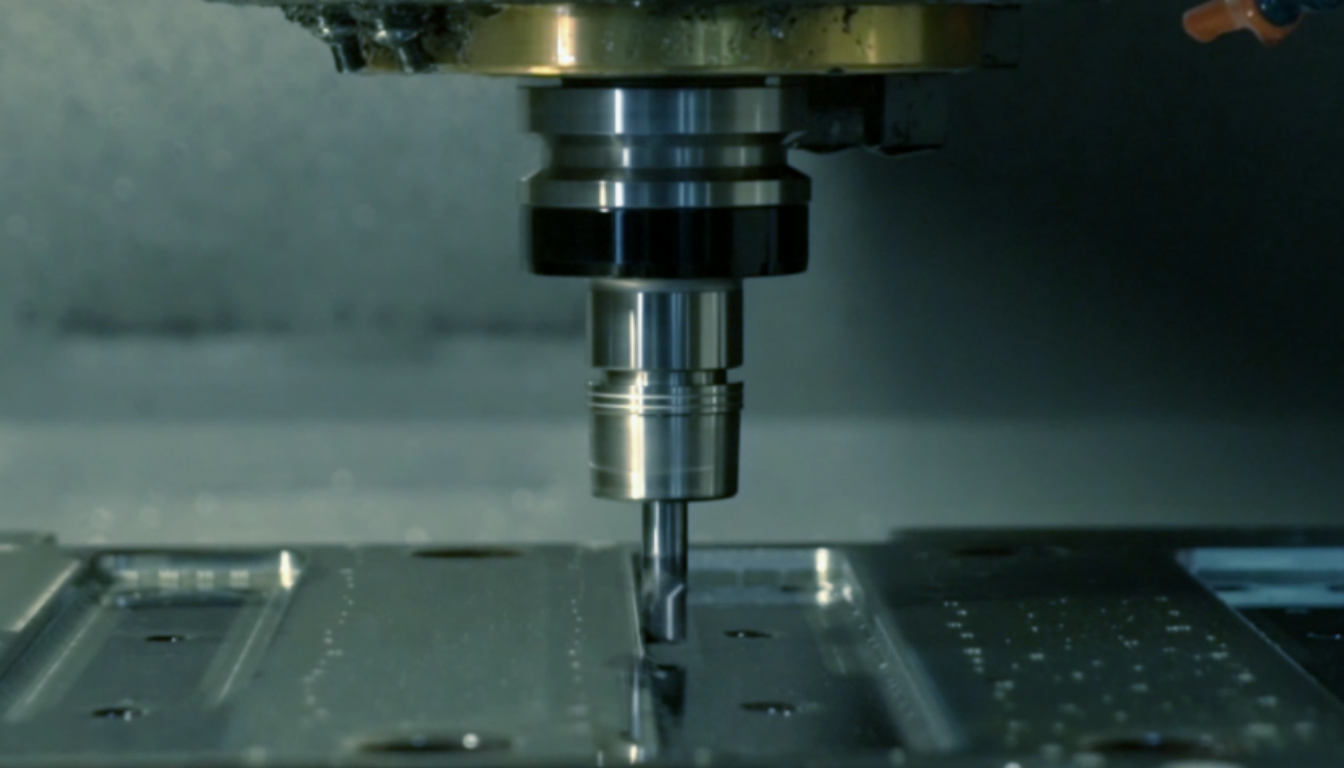

Machining & Fabrication – CNC machining, EDM, and precision grinding.

Assembly & Testing – Mold assembly followed by trial runs and adjustments to ensure performance and accuracy.

Design & Engineering – Product and mold design based on part requirements and material selection.

Material Preparation – Selection of appropriate tool steel or mold materials.

Machining & Fabrication – CNC machining, EDM, and precision grinding.

Assembly & Testing – Mold assembly followed by trial runs and adjustments to ensure performance and accuracy.

No, a die and a mold are not the same. A mold is mainly used for shaping plastic parts through injection molding, while a die is used for metal forming processes such as stamping or forging. Although both serve similar shaping functions, they differ in application, structure, and operating processes.