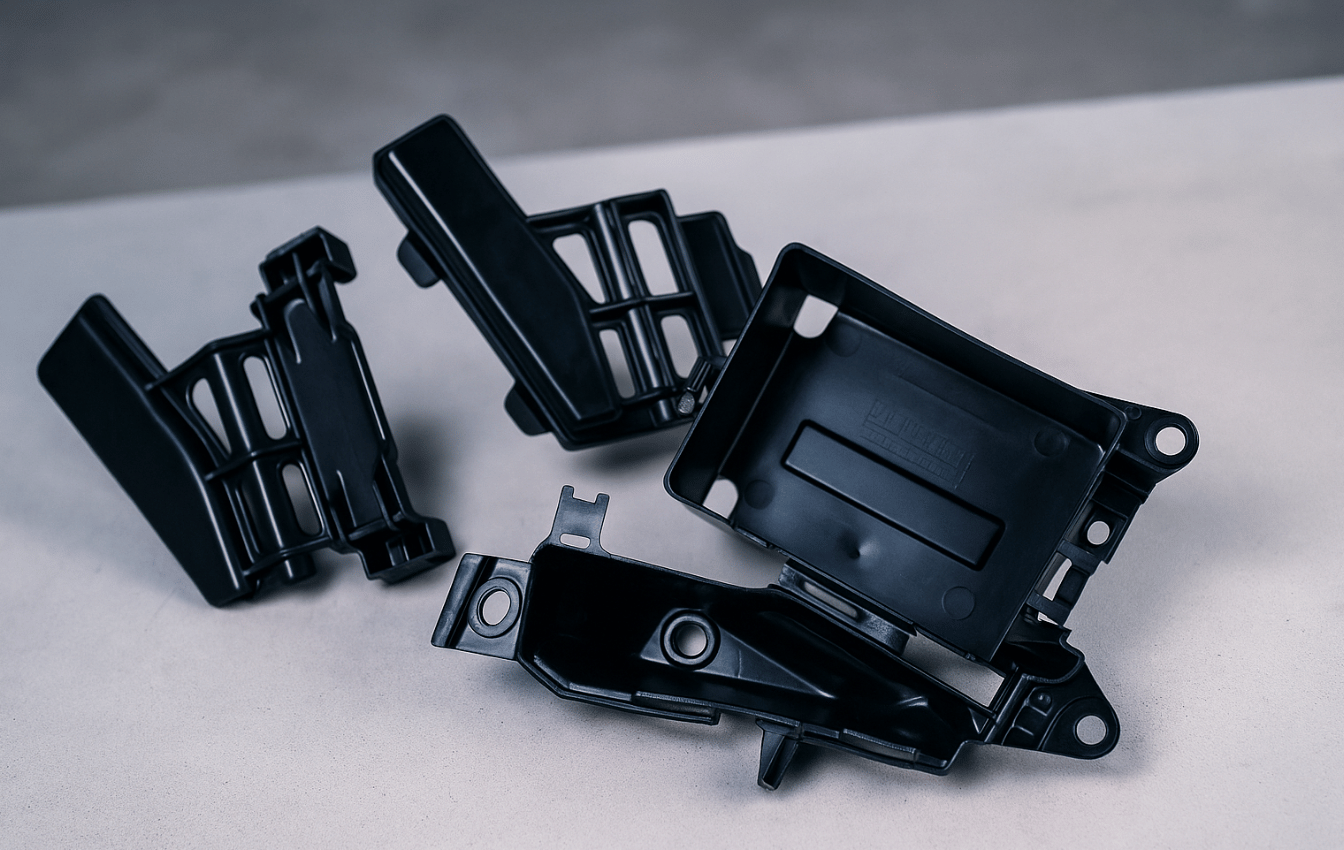

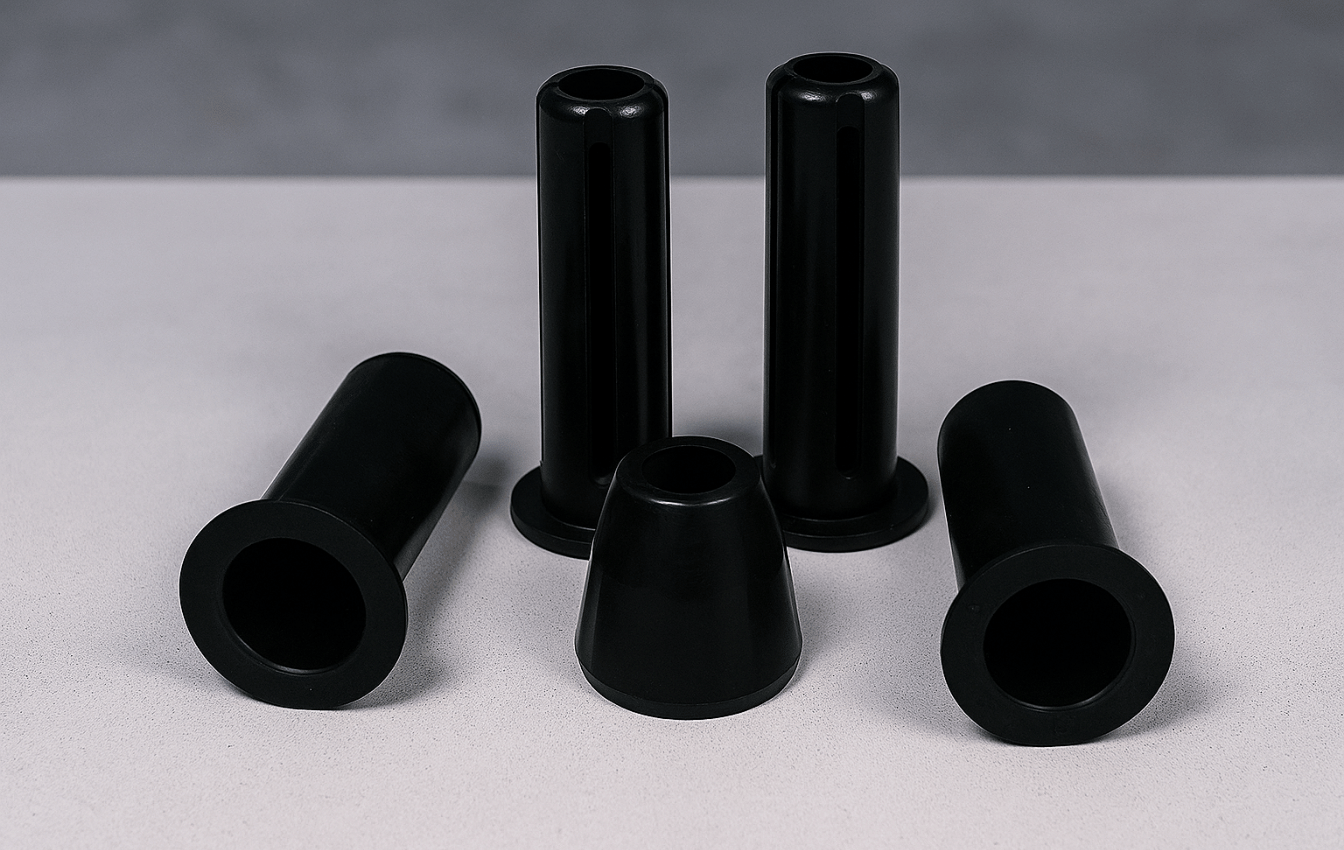

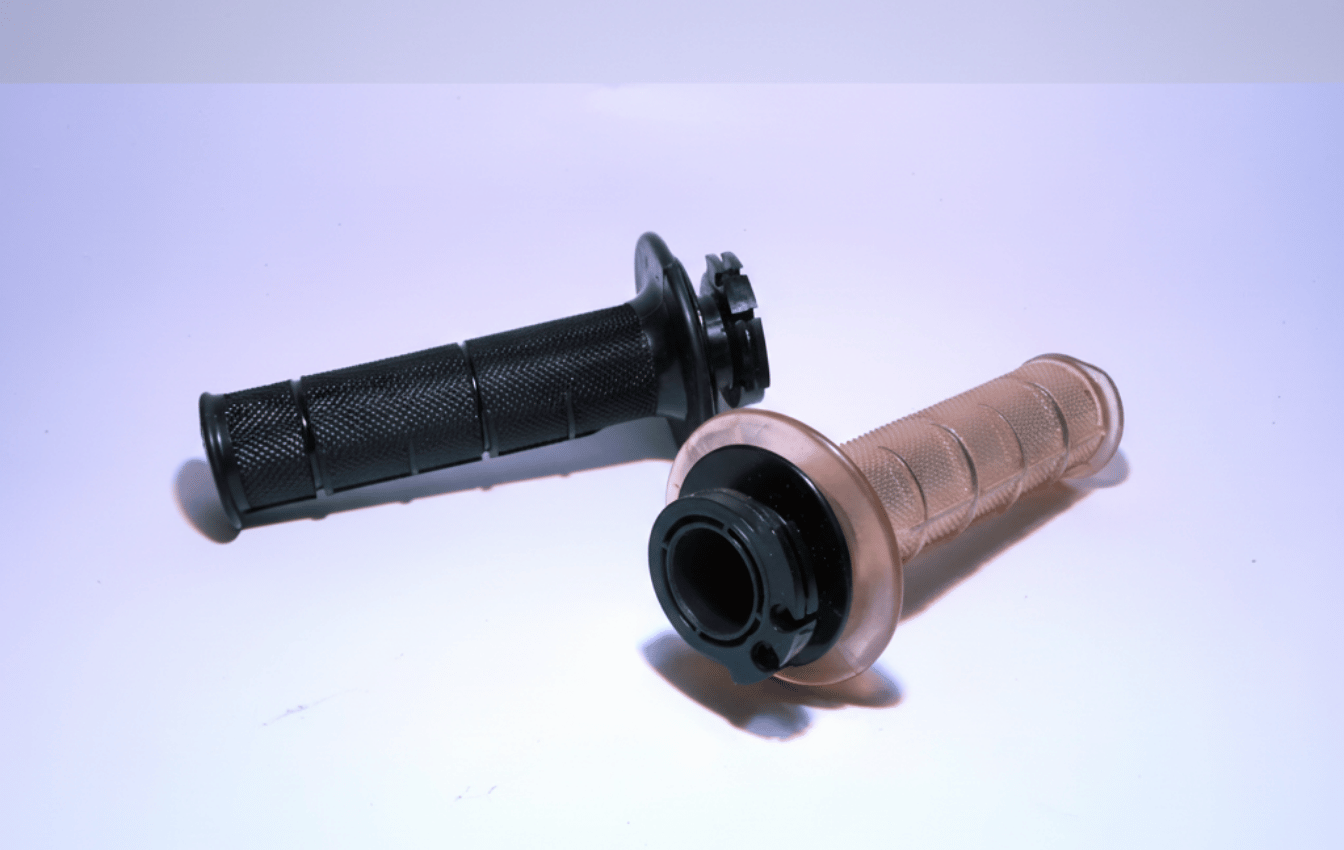

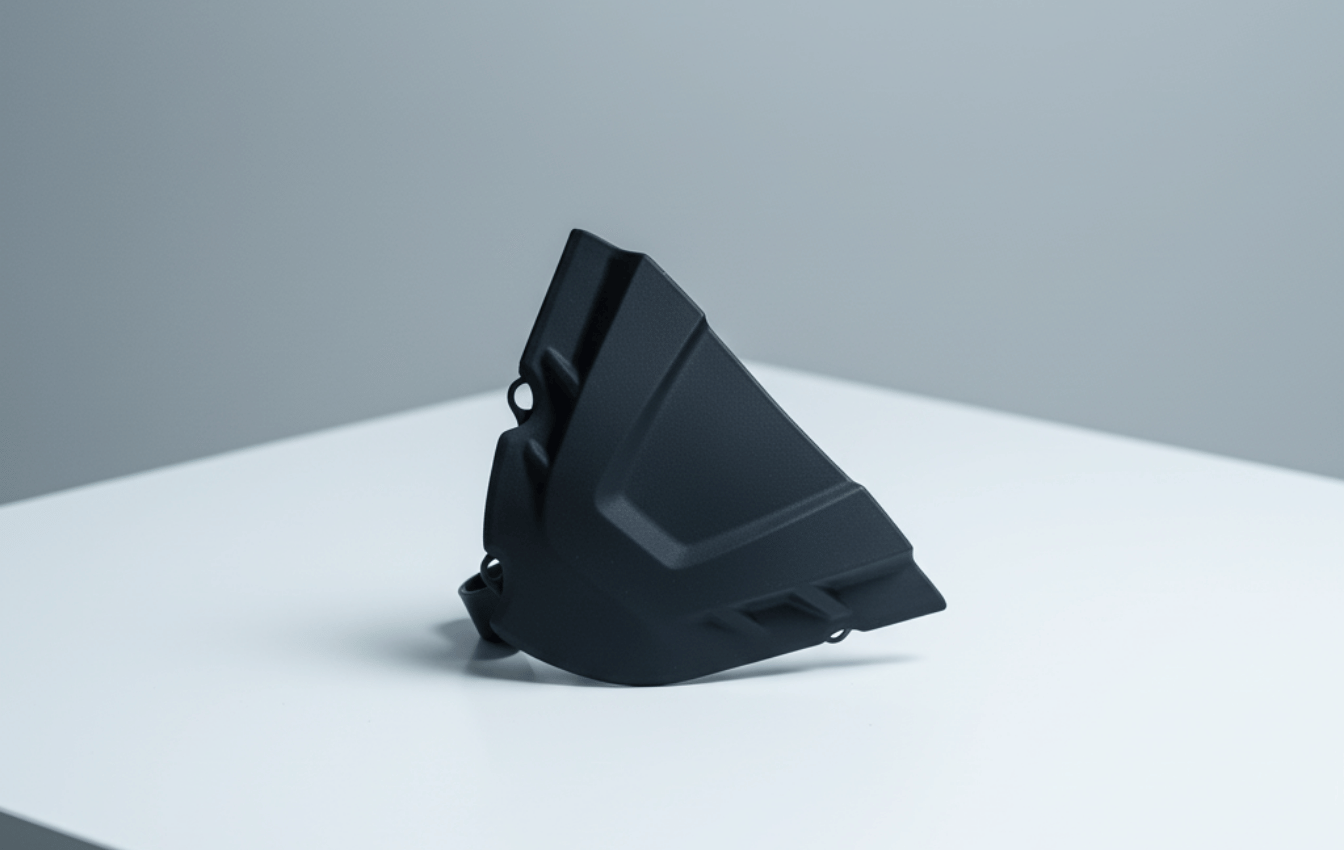

Custom Plastic Injection Solutions for Motorcycle Components

Precision-engineered plastic parts for durability, safety, and mass production.

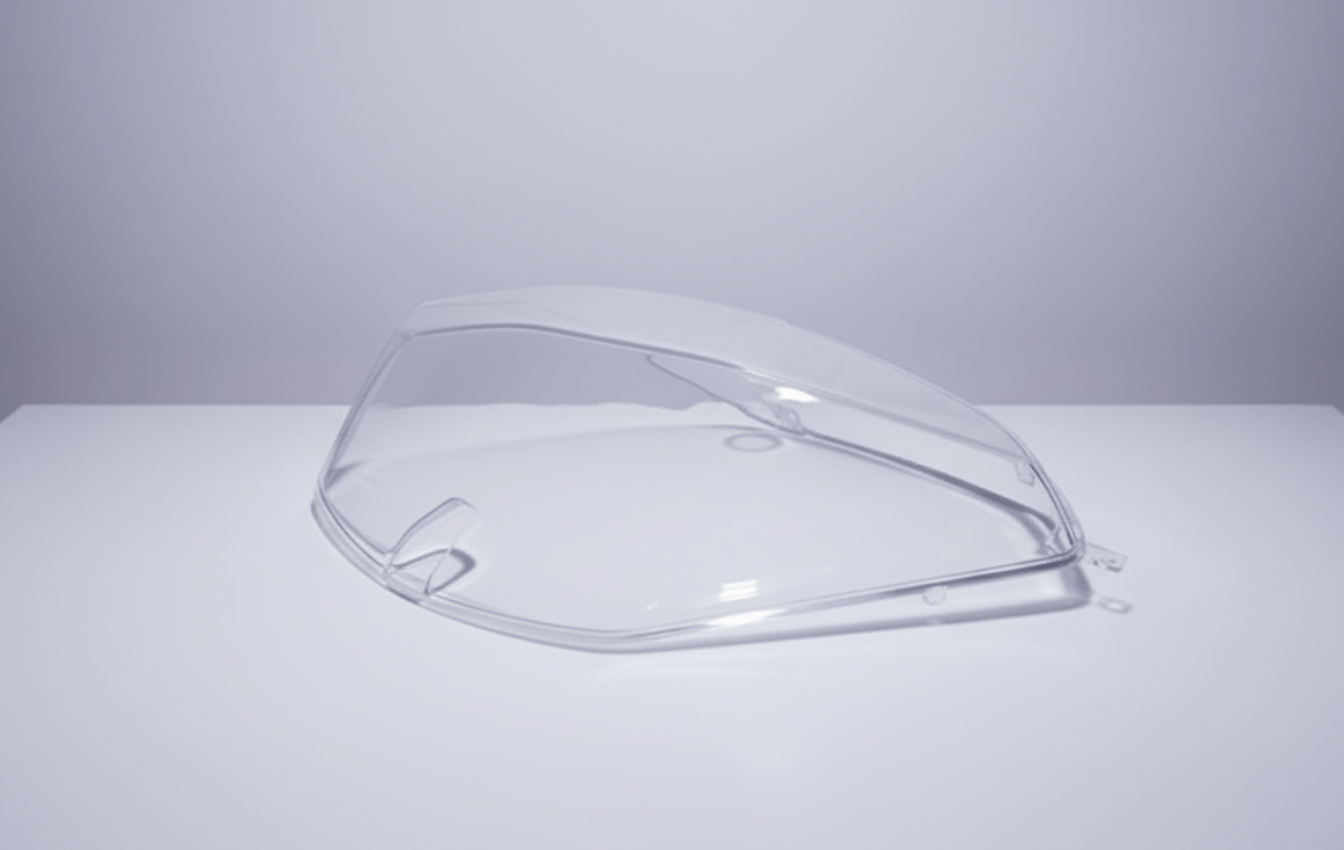

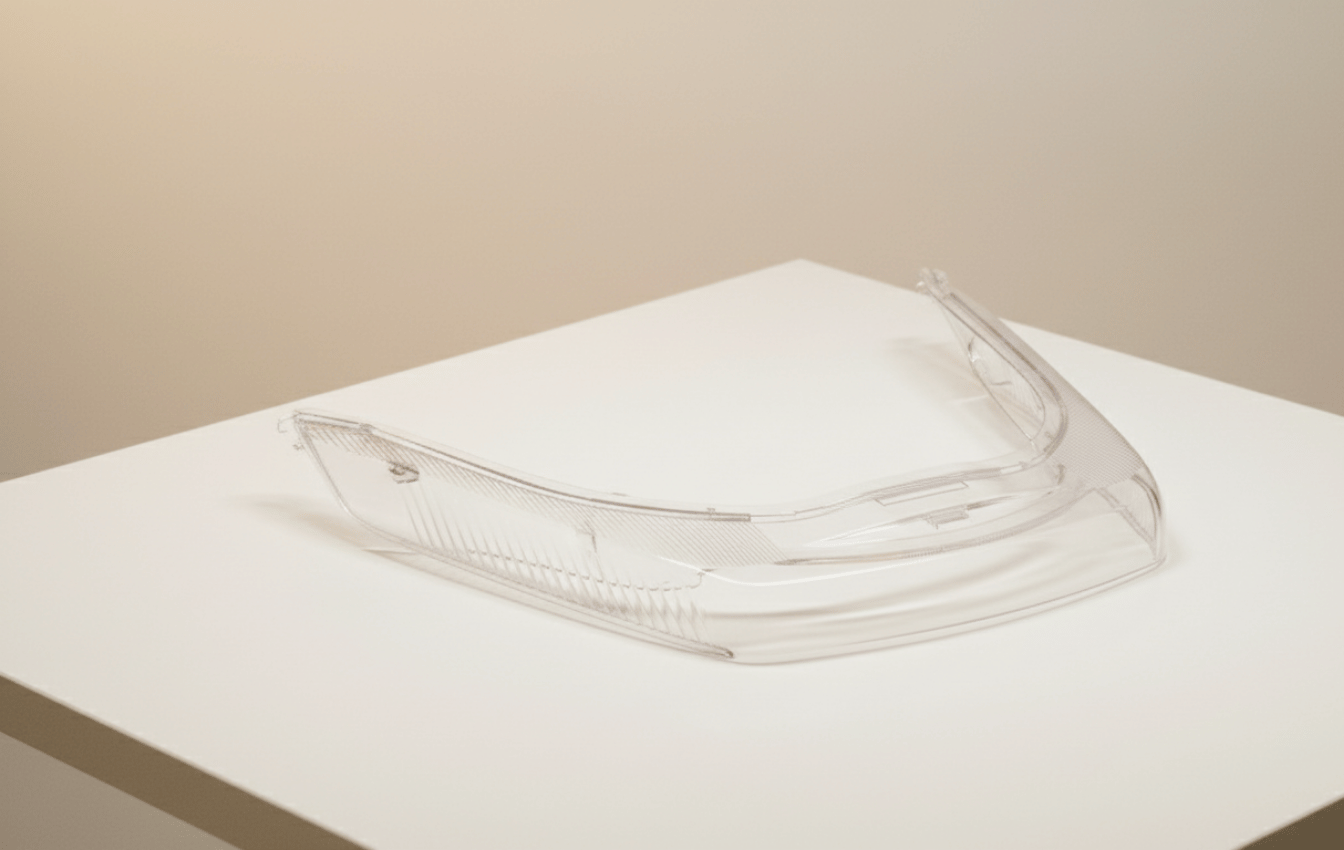

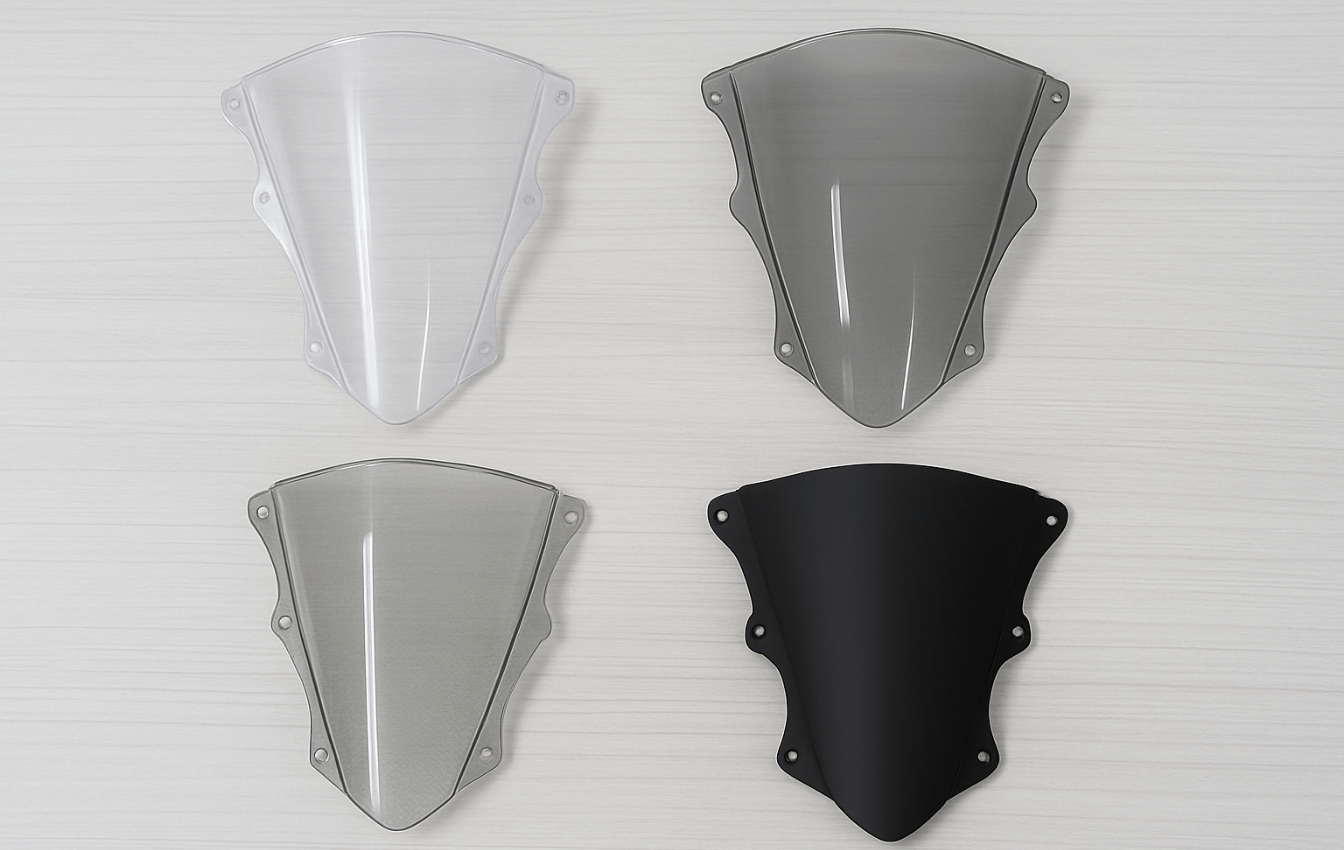

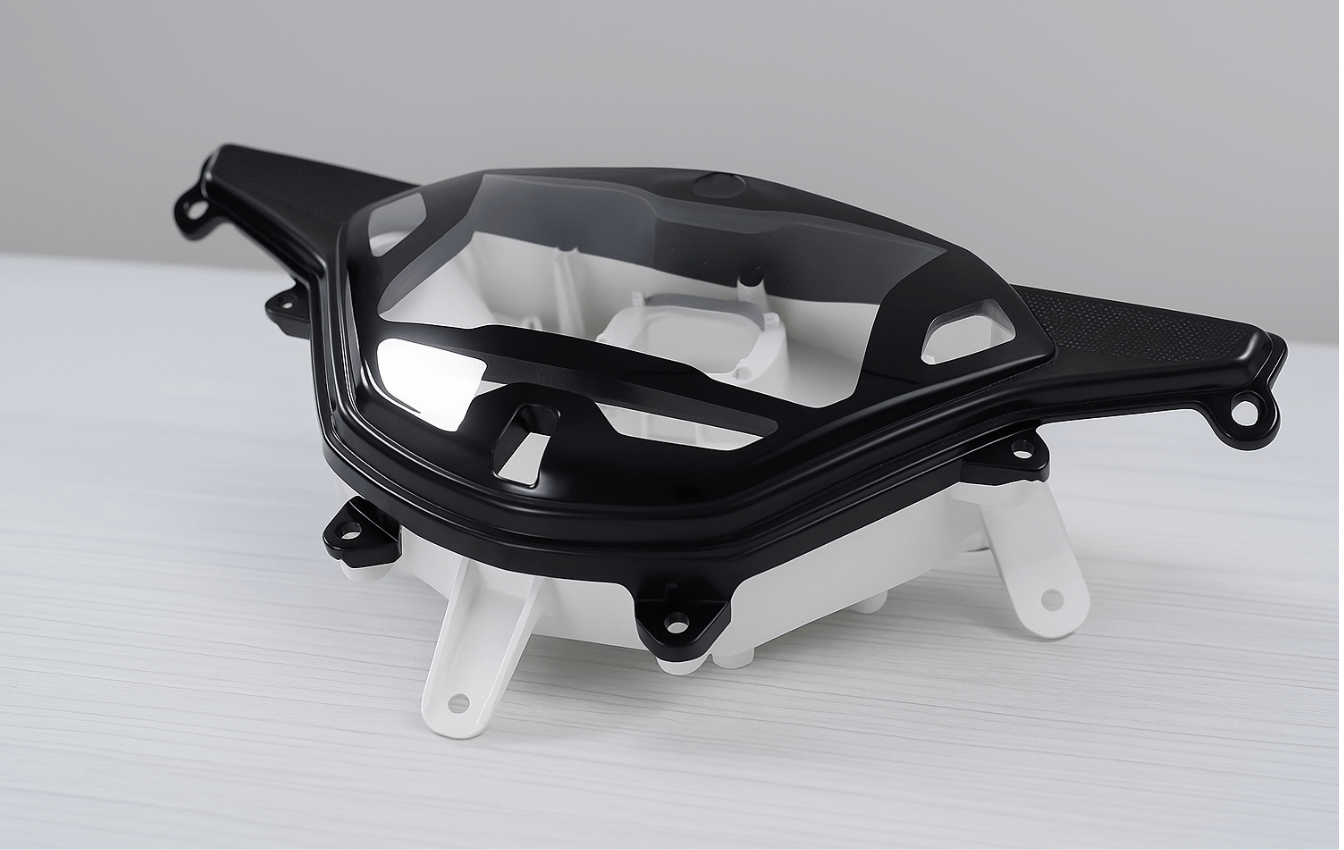

Motorcycle Parts We Manufacture

Mold & Tooling Engineering for Motorcycle Parts

Optimized Mold Design

Mold structures engineered specifically for motorcycle part geometry and production efficiency.

Multi-Cavity & Family Mold Capability

Designed to support high-volume production while maintaining consistent part quality.

Mold Life for Mass Production

Tooling engineered for long service life and stable performance over extended production cycles.

DFM Support

Design-for-manufacturing analysis to reduce cost, improve moldability, and shorten cycle time.

Quality Control & Automotive-Oriented Standards

Incoming inspection

Verification of material specifications before production to ensure consistency.

In-process & final QC

Continuous monitoring during molding to maintain dimensional and visual quality.

Dimensional validation

Inspection processes to ensure parts meet drawing and assembly requirements.

Certification (ISO)

Manufacturing processes aligned with ISO quality standards for reliability.