Custom Plastic Injection Molding Service

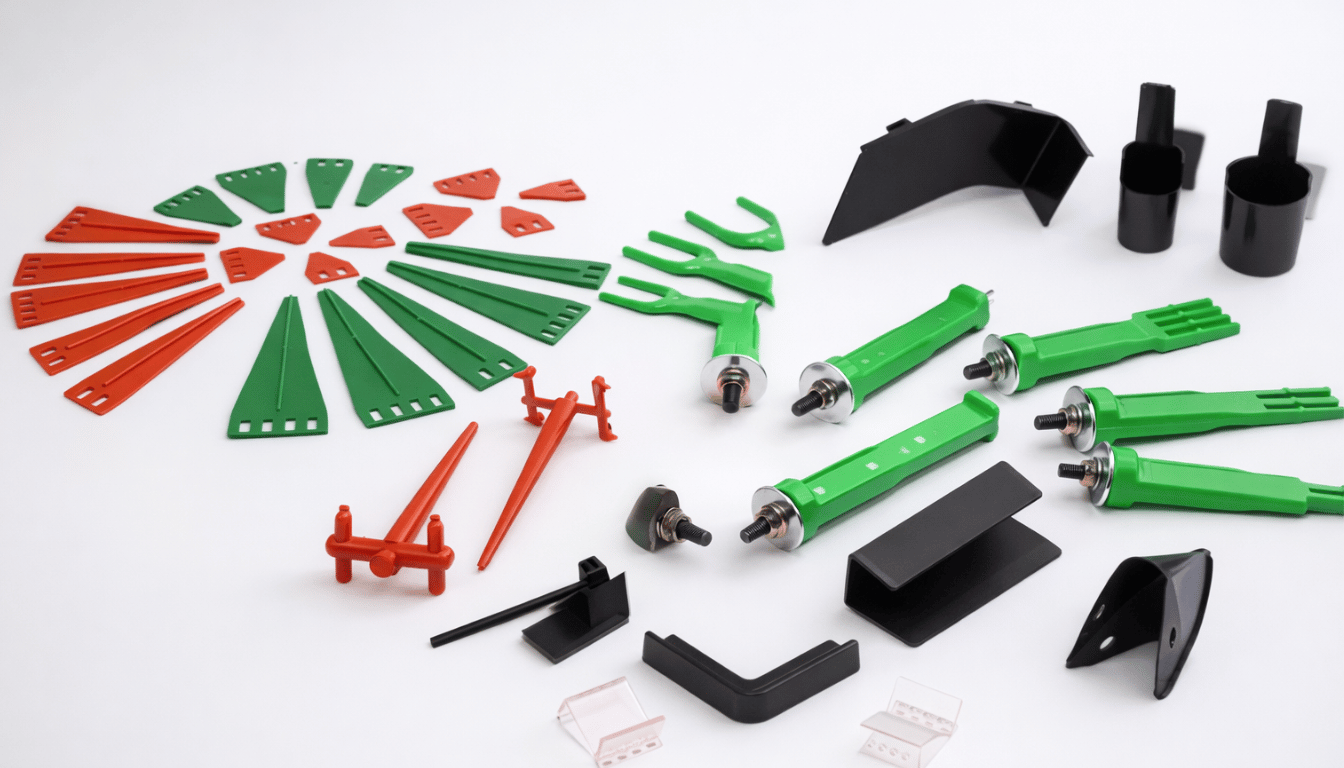

We provide engineering plastic injection molding solutions for a wide range of manufacturing industries, including automotive (automobile and motorcycle), home appliances, and electronic components. By utilizing engineering plastics with proven strength, durability, and functional performance, we produce high-quality plastic parts with stable dimensions, consistent quality, and dependable performance, supporting reliable and efficient mass production.

Our High Quality Materials

- PC (Polycarbonate)

- Known for its excellent impact strength and optical clarity, ideal for automotive and electronic components

- PMMA (Polymethyl Methacrylate)

- Delivers superior transparency and surface finish for high-precision optical and aesthetic parts

- PBT (Polybutylene Terephthalate)

- Offers great dimensional stability and heat resistance, perfect for electrical and mechanical applications

- PA (Polyamide)

- Engineering plastic known for high strength, electrical insulation, and heat resistance, widely used in automotive and electrical parts.

- POM (Polyoxymethylene)

- Versatile and cost-effective plastic combining toughness, rigidity, and smooth surface finish, suitable for various industrial applications.

- ASA (Acrylonitrile Styrene Acrylate)

- Strong and dimensionally stable thermoplastic with excellent chemical resistance, ideal for mechanical and structural components.

- PP Compound (Glass Fiber, Talc, UV, etc.)

- Engineering polypropylene material offering reliable strength, durability, and stable molding performance for consistent quality in mass-produced plastic components.

- ABS (Acrylonitrile Butadiene Styrene)

- Engineering thermoplastic offering good strength, impact resistance, and surface quality for consistent performance in mass-produced plastic components.

Fully Integrated Process

Step 1

Inquiry & Requirement Confirmation

Customer submits an inquiry, drawing, or sample. Our team reviews the product application, specifications, and production requirements.Step 2

Feasibility Study & Quotation

Engineering conducts a feasibility study on design and manufacturing processes, followed by cost calculation and quotation submission.Step 3

Product Development & Mold Preparation

Mold design, review, and sampling trials (T0–T1–T2) are performed to ensure the product meets technical and quality requirements.Step 4

Approval & Production Planning

After sample approval, quality documentation, machine capacity, and production planning are prepared for mass production readiness.Step 5

Mass Production & Quality Assurance

Mass production is executed with continuous monitoring of output, quality performance, and on-time delivery to the customer.Mold & Tooling Capabilities

- Lead Time

- We offer efficient turnaround, completing most orders within 15 working days

- Minimum Part Size

- 10 mm

- Maximum Part Size

- 1000 mm

- Mold Cavities

- Single-cavity molds, multi-cavity molds, and family molds

- Minimum Size Mold

- 150x150 mm

- Maximum Size Mold

- 1000x1500 mm

Certified for Quality and Reliability

ISO 14001:2015

IATF 16949:2016

ISO 9001:2015

Why Choose Banshu Plastic

Integrated Engineering & Manufacturing

From design to mass production, every process is handled in-house to ensuring precision, speed, and consistent quality.

Certified Quality & Global Standards

Our quality system complies with ISO 14001, ISO 9001, and IATF 16949, supported by strict inspection and continuous improvement culture.

Proven Experience & Trusted by Industry Leaders

Decades of experience serving automotive, electronics, and home appliance manufacturers across Asia.

Industries Served

Quality Molded Parts for Your Industry Needs

Automobile Parts

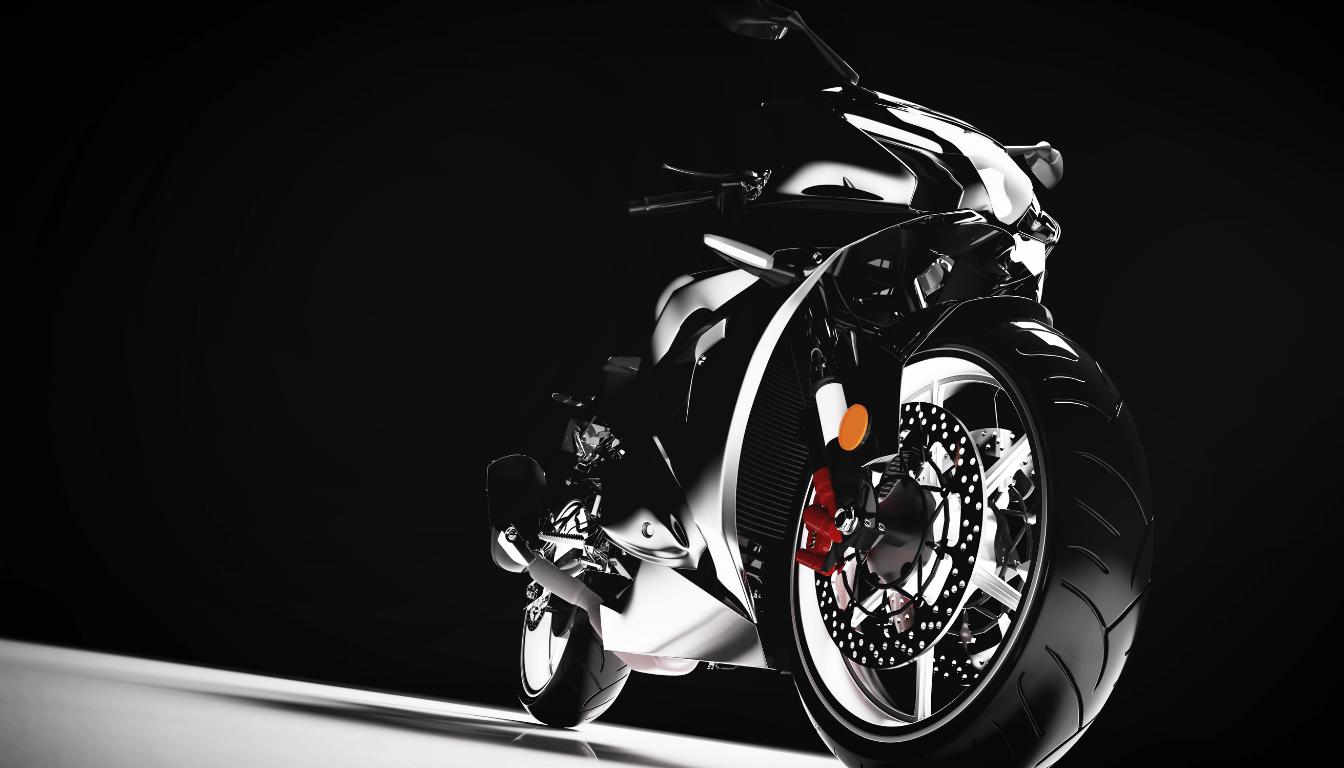

Motorcycle Parts

Home Appliance Parts

Other Parts

Frequently Asked Questions

Plastic injection molding is a manufacturing process used to produce plastic parts by injecting molten plastic material into a precisely engineered mold. This method enables high accuracy, consistent quality, and efficient mass production for complex and tight-tolerance components.

The purpose of injection molding is to manufacture plastic parts efficiently, consistently, and at scale. It is widely used to produce high-quality components with complex geometries, excellent surface finish, and stable dimensional accuracy for industrial and OEM applications.

The injection molding process generally consists of four main steps:

Clamping: The mold is securely closed and held under pressure.

Injection: Molten plastic is injected into the mold cavity.

Cooling: The material cools and solidifies into the desired shape.

Ejection: The finished part is released from the mold.

Clamping: The mold is securely closed and held under pressure.

Injection: Molten plastic is injected into the mold cavity.

Cooling: The material cools and solidifies into the desired shape.

Ejection: The finished part is released from the mold.

Minimum order quantity (MOQ) depends on the part design, material selection, and tooling requirements. At Banshu Plastic, we support both low-volume production for new projects and mass production for established OEM programs, with flexible discussion based on customer needs.

Injection molding uses a wide range of plastic materials, with a strong focus on engineering plastics for industrial and OEM applications. At Banshu Plastic, we predominantly process materials such as PC, Nylon (PA), POM, reinforced resins, and flame-retardant grades that offer superior strength, heat resistance, dimensional stability, and electrical safety. Material selection is tailored to meet specific mechanical, thermal, and regulatory requirements of each application.